Modern construction stores amaze with the variety of their assortment for finishing of housing. And ceramic tiles remain one of the favorites for finishing of walls and floors in rooms with high humidity or the need for frequent wet cleaning. These are mainly bathrooms, kitchens, corridors and hallways, as well as balconies and loggias, and some non-residential premises.

If you are not a specialist in apartment renovation, then laying tiles yourself will not be an easy task. Therefore, many trust this work to professionals – tiling masters. However, if you still decide to lay ceramic tiles yourself, then you must strictly adhere to the technology of work. Namely, lay the tiles in several stages:

- Preparation of necessary tools and materials

- Preparing the surface for laying tiles

- Surface marking

- Laying ceramic tiles on the floor

- Laying ceramic tiles on the wall

- Cutting tiles

- Grouting tile joints

- Conclusion

By performing the work in this order, you will achieve good results. Below we will examine each stage in more detail.

Preparation of necessary tools and materials

Before starting repair work, you need to purchase the ceramic tiles themselves, adhesive for laying the tiles, and grout for the seams.

When choosing ceramic tiles, you should pay attention not only to the decorative qualities of the coating, but also to the area of application of this tile. The right choice of tiles is the key to its safe and long-lasting service to your home.

First of all, you should choose the tile based on the place where you will lay it. It is worth noting that wall tiles should never be used for floors, as they are too fragile for this and will not withstand such mechanical loads. And vice versa – floor tiles are too heavy to lay on walls.

The next element is the texture. For safety reasons, tiles with a rough texture are more suitable for the floor, which will prevent slipping, especially on a wet floor. Such textures are: unglazed tiles, lapped tiles (semi-polished, polished), matte (natural, unpolished), structured tiles (embossed, textured, textured). Such types of tiles are distinguished by their practicality, wear resistance and anti-slip effect.

And such types of tiles as glazed tiles, glossy and polished will look great on the walls. Such types of tiles look very impressive and beautiful, but they are more fragile and become too slippery when wet, therefore they are rarely used for finishing floors. Nevertheless, it is permissible to use such tiles on the floor, for example, in the living room. However, do not forget about practicality in the pursuit of beauty.

Among other things, be sure to ask the hardware store for the relevant documents for the tile, which will indicate its main operational and physical-technical indicators. This way, you can make sure whether this type of tile is right for you or not.

As for the sizes of ceramic tiles, if you do not have the necessary experience in laying tiles, then you should not chase after too large or small tile sizes. The best option for you will be medium-sized tiles with sides from 20 to 40 cm. When checking the tiles delivered to you, pay attention to the fact that the article number, shade and production batch on the packaging match. The fact is that tiles from different production batches may differ slightly visually, which may become noticeable after laying the tiles.

It is necessary to buy tiles with a reserve, some tiles may be used for cutting, and you should not exclude damage to tiles during work. The optimal reserve size is 10%, but if you plan to make a diagonal arrangement of ceramic tiles, it is better to make a reserve of 15% of the main amount.

Dry mixes are now the ideal choice for tile adhesive. In the store, you can find many options for adhesive mixes from economy to premium class. For self-laying of ceramic tiles, it is best to choose an adhesive mix from the middle price category, which does not require special skills. You will only need to properly dilute the adhesive in accordance with the instructions.

The final stage of tiling will be grouting, which should also be purchased in advance.

The amount of grout required depends on:

— from the size of the tiles (the smaller the tiles, the more seams there will be in the end);

— from the thickness of the tile (the seam must be tightly filled to its full depth);

– from the planned gap between the tiles (it also determines the volume of the seam);

— from the total area of the covering to be faced.

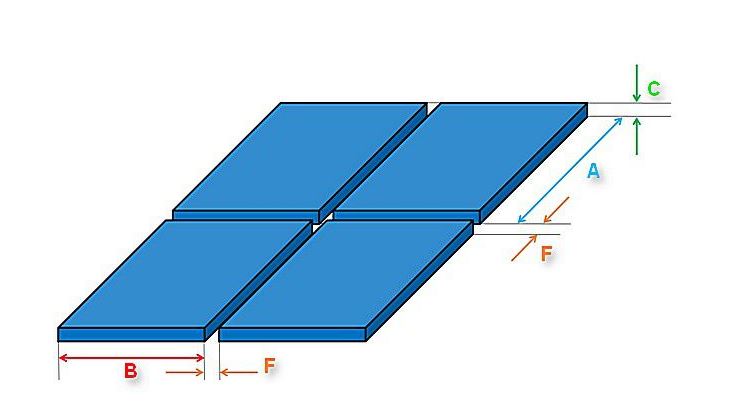

Scheme for better understanding of calculation of amount of grout

A – length of ceramic tile;

B – tile width;

C – tile thickness;

F – the size of the planned gap between the tiles.

The general dependence can be expressed by the following formula:

Vs = ((A + B) / (A × B)) × C × F × kp

Vs is the consumption of tiles in kilograms per unit area (m²);

kp – coefficient taking into account the density of the grout. It varies slightly among different brands, but it would not be a big mistake to take the average value of 1.75 g/cm³

To get the required amount for finishing a certain surface, all that remains is to multiply the obtained value by the area and add another 10% reserve.

Σv = Vs × S × 1.1

Preparing the surface for laying tiles

Do not lay tiles without pre-treating the surface. The main requirements for surfaces before laying are that they must be reliable and even. If there are finishing coatings on the surface, they must be completely removed. And then carefully check the surface for defects.

If you are going to lay tiles on the wall, you also need to find out what condition the previous rough finish is in. If cracks or peeling are visible on the plaster, it must be removed to the base. If the plaster layer looks strong and reliable, you can continue working with it without dismantling the plaster. You should also pay attention to the quality of the walls themselves. If you are going to lay tiles in a secondary apartment, it is likely that the walls between the bathroom and toilet, as well as between the bathroom and kitchen, may no longer be suitable for major repairs. Then you will have to demolish the old partitions and erect new ones, and then prepare the walls for further work.

In addition to the old, unusable layer of plaster, you may also encounter such an unpleasant problem as mold. In this case, the walls must be treated with a special compound that will help get rid of mold. The affected area of the wall will need to be cleaned, and then the compound applied according to the instructions. Here you should be scrupulous and thoroughly clean the wall from microflora, since even clean and healthy-looking walls can already be affected by mold. Therefore, it is worth treating all the walls entirely. This stage cannot be neglected, since this can lead to further damage to the repair.

The next step after treating the walls will be applying a primer with an antiseptic effect, preferably in 2 layers. Before applying the second layer, it is necessary to wait until the first one is completely absorbed.

Next, you need to choose one of the methods of leveling the walls based on your conditions – plaster, putty or leveling with gypsum board. It is not necessary to achieve ideal smoothness of the walls, since you will not glue wallpaper or paint the walls, but the roughness of the surface should be in moderation. Accordingly, if the walls have a large number of defects, it is better to do a complete plastering of the walls, and if the defects are insignificant, then you can do with putty. In some cases, you can use wall leveling with gypsum board, for example, when building new partitions or to quickly achieve a flat surface. And as a final stage, again prime the walls in 2 layers.

As for the floor, the main requirement is the same as for the walls – it must be level (in some cases, a slope for draining water is possible), reliable and durable, and also free from mold.

The first thing to check is the floor screed. If there are any loose unstable areas, they need to be removed. In this case, the surface needs to be cleaned down to solid concrete. After the old floors have been completely dismantled, a new floor screed needs to be made and a horizontally leveled surface needs to be prepared. You also need to remember about high-quality waterproofing in a room with high humidity. If the screed is generally in satisfactory condition, you can limit yourself to cosmetic repairs. After working with the screed, the surface needs to be cleaned and thoroughly primed with a deep penetration compound.

Surface marking

After the preparatory work, you can start marking the surface. For this, you will need slats. You can make them yourself. To get slats, you should saw straight wooden bars to the required length. Products with a length of 1.5 meters are considered universal. The next step is to apply markings to the slat using a felt-tip pen or pencil. It should fully correspond to the dimensions of the facing material. You need to lay out the tiles lengthwise, place crosses between them, put the slat on the row and mark the edges of each tile in the row. If the facing material is square, then it is enough to use one slat. For tiles of different lengths, it is appropriate to use two slats. It is extremely important to ensure that the slat does not shift when applying the markings.

Laying ceramic tiles on the floor

It is recommended to start laying ceramic tiles from the entrance to the room. It is recommended that you mark the area where the tiles will be laid at the very beginning with a pencil or chalk. In addition, you can draw lines perpendicular to the entrance to the room. Then you can start placing the facing material along the lines. Important to know! Crosses must be placed between each tile. These elements help create the required distance.

The next step is to apply the adhesive using a trowel or a notched trowel. The adhesive should be thrown onto the floor so that its shape completely matches the tile. After that, you can start laying the facing material on the floor surface where the adhesive was applied. You should check the correctness of its installation using a level. First, it should be placed along the length of the tile, and then diagonally. If one material is higher than the other, then place a flat block of wood on it and tap it a little with a rubber mallet. If the tile is lower in level, then add a little more tile adhesive.

In some areas, the tiles need to be cut. To do this, you need to measure the distance between the last laid tile and the wall. It should be 1 cm. It should be marked on the tile that you plan to cut. You need to cut the material along the line using a glass cutter or grinder. Then you need to apply the glue. It will take 24 hours for it to dry completely.

Next, you can start filling the seams with a special mixture. Before preparing it, you need to carefully study the manufacturer’s instructions. A rubber spatula is used to fill the seams. It should be placed at an angle of 45 degrees.

Laying tiles on the wall

Laying tiles should be done from the bottom up. First, place a row of tiles above the floor, and then gradually move up. To ensure a smooth surface, it is recommended to lay the first row on a wooden slat. In addition, you should use vertical slats in the corners. They provide the following rows with a perfectly smooth surface horizontally. Next, nails should be driven into the wooden slats. A strong thread should be pulled between them.

The next step is to apply tile adhesive to the tiles using a notched trowel. Sometimes it is appropriate to add it to the wall. The tiles should be pressed tightly against the wall. You should place crosses between the tiles. The gap should not be more than 4 mm. It prevents the tiles from peeling off when exposed to high temperatures. It is recommended to use a level to control the evenness of the installation.

Cutting ceramic tiles

In order for this procedure to be carried out successfully, you need to pay special attention to the quality of the materials. To obtain straight lines, use a manual tile cutter. If you do not have one, you can use a drill, nail, or glass cutter. First, you need to make an even scratch, after which you can begin to divide the tile into 2 parts by applying uniform pressure to the corner of the table.

Don’t forget about the outer corners! The modern construction market offers products that are easy to put on adjacent tiles. Professionals rarely use them. Instead, they cut the corner tiles at an angle of 45 degrees using a grinder or an electric tile cutter. The tiles are cut to the glaze on the outside. The angle should be large (to avoid difficulties when joining).

Sometimes you need to make holes in the tiles. To make small holes, you can use a tile drill, and to make large holes, you can use a ballerina or crown drill. To make square holes, you can use a grinder.

Grouting tile joints

Most tile adhesives harden 24 hours after application. But there are products that dry after 4 hours. In order for the grouting to be successful, you must first remove the plastic crosses and clean the joints from the solution. This step is quite simple and clear. To grout the tile joints, you need to mix the mixture with water and remove the excess with a clean cloth. If the room has a large area, then it is strongly recommended to use a rubber float.

There is a relief decor that is difficult to cover up. In such cases, you should seal it. In rooms with high humidity, it is recommended to provide reliable protection for the seams using a special impregnation.

Conclusion

Laying ceramic tiles on the floor or wall is a rather complicated and responsible process consisting of many stages. In order to avoid mistakes during repair work, it is necessary to carefully study each point. In addition, the result of your work largely depends on the quality of the tools. This issue is especially relevant in cases where it is necessary to cut tiles.