There is an opinion that owners of private houses are constantly “patching”, forging, improving something. There is some truth in this, but the main repair work is carried out at one time, so it is easier to allocate free time from the work schedule and control the work. Traditionally, repairs are postponed until summer vacations. But is there any point in wasting a long-awaited vacation like this? Is it possible to repair a house in winter?

What kind of work is done in winter and what kind is done in summer?

Not all repairs can be carried out in winter. For example, it is worth postponing the replacement of radiators or the entire heating system, installation of windows and doors, removal of old pipes or installation of air conditioners until summer. Low temperatures can damage connecting elements, reduce the performance of communications equipment. Also, do not seal cracks in the foundation and walls in winter.

But interior finishing can be done at any time of the year – pouring screed, painting walls, gluing wallpaper, laying tiles. The main thing is to monitor the temperature conditions inside the room. Usually, materials are allowed to be used at temperatures up to +5° C, at lower temperatures, building mixtures can lose their properties (but everything depends on the manufacturer’s recommendations). That is, repairs can only be done in those houses that are already connected to the heating system. Or there is an external heating system.

In winter, you can also replace the electrical wiring and completely renovate the kitchen.

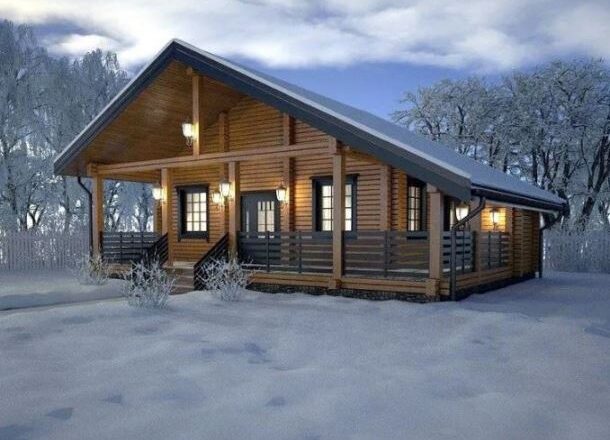

DoorHan specializes in building houses at any time of the year. The technologies we use allow us to build safe and high-quality buildings both in summer and winter. You can start finishing immediately after the facility is handed over.

Interior decoration

If the house or cottage is heated, then interior work can be carried out regardless of the weather and time of year. It is enough to follow simple rules:

- It is necessary to maintain a constant temperature in the room within 18-20 °C. Moreover, not only during the repair, but also after its completion.

- The humidity level should not exceed 60%, the minimum is 30%, ideal conditions are 45%.

- It is not recommended to start finishing the walls immediately after starting the heating. It is necessary to wait until all surfaces are completely dry, because of humidity the quality of work decreases.

- It is not allowed to open windows for ventilation. It is also worth turning off air conditioners during work. Drafts are the most common mistake of novice craftsmen. Many mixtures contain water, which freezes at sub-zero temperatures. Cold air is especially destructive for plaster, concrete mixtures, glue.

Also, you can’t use building materials immediately after purchasing them. Floor coverings, some adhesives and finishing compounds can change their properties when transferred from cold to warm, so they need to be given time to stand, to come to normal with room temperature.

Repairs are allowed in unheated houses. But in this case, special heat guns will be needed. They help maintain the temperature at one level.

If the characteristics of the material do not allow its use in winter, it is worth looking for analogues adapted to extreme conditions. For example, floor screeds are often made of concrete. This is an inexpensive and effective way to arrange a rough base. But concrete contains a large amount of water, its drying can take a long time – a month, a month and a half or even more. All this is fraught with delays and postponements of the deadlines for the delivery of the object.

As a substitute for the “winter” option, you can use a semi-dry screed. The building material is also based on concrete, but it contains much less water, and the laying technology is different. It took only a few days for such a floor to fully set.

Exterior finishing

When it comes to exterior finishing, the fundamental factor is the ambient temperature and weather conditions. Some building materials are very sensitive to frost, rain or excessive humidity.

For example, flexible tiles can only be installed at +5 °C and in sunny weather. The whole point is that the installation of soft roofing has its own characteristics. The panels are attached to a specially prepared base using an adhesive layer located on the back of the sheet.

After fixing, the surface of the tiles heats up, the heat activates the adhesive binders and it melts, forming a strong, dense waterproof layer. In winter, the sun is not as bright, the temperature is lower and the reaction may not occur. All this will negatively affect the performance of the roof. That is, it is better to postpone the installation of flexible roofing until spring or summer.

The same applies to the “wet facade” technology. The manufacturer allows finishing with such materials at a temperature slightly below +5 °C. Decorative elements with a heat-insulating layer are attached to the walls using special fasteners and glue. To prevent the glue from drying out and crumbling at low temperatures, salt is added to its composition. But in the spring, with the arrival of warmth, white streaks may appear on the walls, worsening the appearance of the facade.

The benefits of winter renovation

The stereotype that repair work cannot be carried out in winter was formed in times when there was not such a variety of building materials. And most compositions were developed without taking into account use in adverse conditions.

Modern finishing materials have compositions that are resistant to frost, heat, and temperature changes. Raw materials for winter work are in no way inferior to classic options, they also “set” perfectly and can serve for many years. Yes, it is more expensive, but it can be used without regard to the surrounding conditions. That is, there are no serious obstacles to carrying out repairs in winter. On the contrary, the market for building materials is actively developing, innovative technologies and approaches to the implementation of interior and exterior finishing are being introduced.

In winter, as a rule, it is easier to find a good master or team. From late autumn to spring, demand for repairs traditionally falls, most people out of habit wait for summer, do not want to take risks. Specialists cannot remain without work for a long time, so they often reduce the cost of their services. So in winter you can “kill two birds with one stone” – easily find an excellent contractor and save on payments.

Another advantage is discounts, promotions and sales of building materials. The prices themselves may not go down, especially in large stores, but sellers are trying to sell out goods from the warehouse, sell last year’s collection, etc. Therefore, we recommend subscribing to the newsletters of several building stores in your city and keeping an eye on interesting offers. Or, if you like shopping, you can go to the stores yourself from time to time and track the assortment.

But all this, of course, is suitable for those who have free time and who do the repairs themselves.

Another pleasant feature of winter repairs is lower transportation costs. In summer, cargo taxis are much more expensive, drivers have many orders and sometimes you have to wait for a car for hours. In winter, there is no such problem. Tariffs are lower, waiting time is minimal.

Features of repairs in winter

As mentioned above, window repair is highly undesirable in winter. Plastic and wood profiles can deform at low temperatures, and seals lose their elasticity.

If it is impossible to postpone the installation, it is necessary to create favorable conditions for this. To protect the room from the cold, special protective screens and heat guns are used. It is also worth taking care of the mounting foam, it should be warmed up in advance – leave it in a warm room for several hours. Otherwise, the foam will lose its original qualities. But it is necessary to take into account the special requirements of the manufacturer, indicated on the packaging.

For winter repairs, it is better to choose materials with a reinforced composition that are not “afraid” of temperature changes, frost, and high humidity.

Thus, we can highlight several disadvantages of home renovation in winter:

- Additional costs. Materials with better characteristics are more expensive than standard ones. There will also be additional costs for heating.

- It is necessary to approach the transportation and storage of water-dispersion paints with special care. At sub-zero temperatures the mixture freezes, and when defrosting, sediment forms. The quality of the paint is significantly reduced.

In winter, there is little daylight. But even in the daytime it is often cloudy, and you have to turn on the lights in the room. Electricity costs, accordingly, will be higher than in the summer, when work can be carried out until late in the evening.

Thus, it is possible to carry out repair work in a private house in winter, but not all of it. There are no obstacles for interior decoration. If the room is heated, you can safely start laying floors and tiles in the bathroom, painting the walls and ceiling, gluing wallpaper, etc.

External works are carried out selectively. For example, there are no obstacles for laying metal tiles or other roofing material resistant to low temperatures. But it is better to postpone the installation of soft tiles, sealing of seams or finishing of facades to the warm season.

There is a simple rule that will allow you to complete the repair as efficiently and qualitatively as possible – always carefully read the manufacturer’s recommendations for the materials produced. This rule is often neglected, and in vain. Strict adherence to the instructions will protect you from unnecessary expenses and will allow you to achieve the desired goal faster.